Want to increase your sales and reduce out-of-stock rates on Amazon? You’ve come to the right place.

Planning shopper demand and managing product availability with Amazon is no easy task. The ecommerce giant is known for short delivery windows, volatile forecasts, and lower stock holding than most other retailers.

Yet, Vendor Managers and AVS will often only provide limited support to overcome these operational challenges. Leaving many suppliers frustrated with inaccurate forecasts and low product availability.

But all is not lost!

Because today, I’m going to show you 10 proven ways to optimise your product availability with Amazon Vendor Central.

Specifically, we’re going to understand:

Let’s get to it.

Why is product availability important when selling on Amazon?

Before we look at how to address product shortages, let’s first understand why keeping your products in stock is important. The answer probably won’t surprise you:

Amazon cannot sell what it does not have in inventory. In other words, if your product is not physically available in one of Amazon’s warehouses, customers will not be able to buy it.

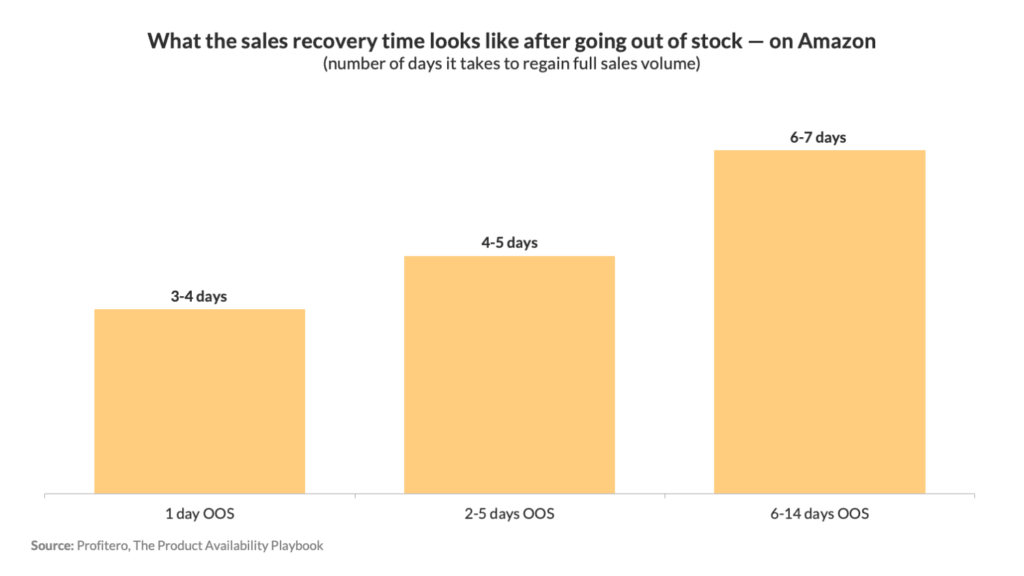

The impact of product unavailability on your sales can be significant: A recent study by Profitero found that it takes an average of 3-4 days to recover revenue after an item has been out of stock on Amazon for 1 day.

Being out of stock also negatively affects your sales rank on the online marketplace. That’s because Amazon will prioritise products that are available and have a reliable in-stock performance in its search results.

Strategies to improve your product availability with Amazon

Now that we understand why keeping your products in stock is important, let’s look at proven ways to enhance your availability with Amazon Vendor Central.

1. Track and benchmark your product availability performance

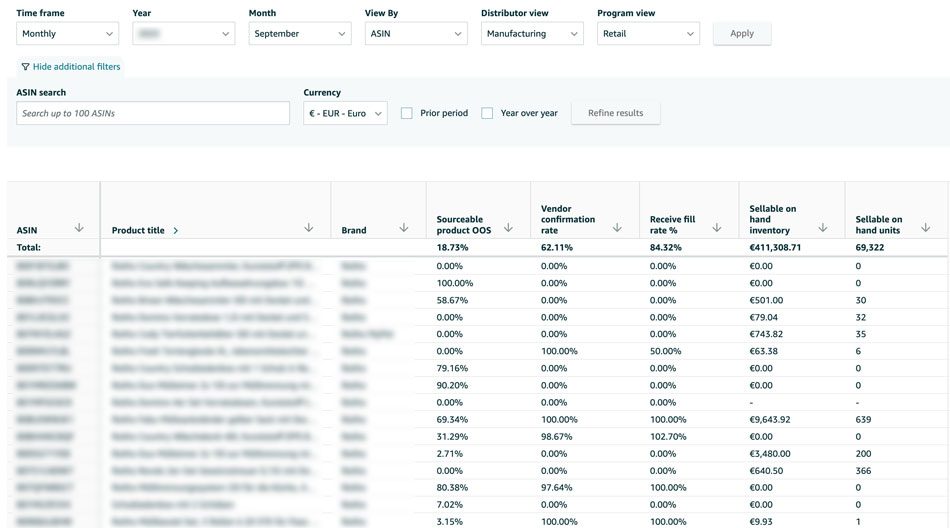

The first thing you want to do is to review your availability performance with Amazon. To do that, log into Vendor Central and click on Reports » Retail Analytics » Inventory.

I recommend you select a time frame of at least one month for your first review. You’ll want to look at three key availability metrics:

- Sourceable Product OOS

- Vendor Confirmation Rate

- Receive Fill Rate

Sourceable Product OOS

This KPI measures the number of times a product is shown as unavailable for purchase on the product detail page when it can be sourced from a 1P vendor.

You want to keep this metric as low as possible. A good target is an OOS rate between max. 5-10%.

Note that the Sourceable Product OOS metric doesn’t include any instances where you lost the Buy Box to a 3P Seller. It primarily measures physical stock unavailability.

Vendor Confirmation Rate

The Vendor Confirmation Rate measures the % of volume you have accepted as a vendor from a Purchasing Order. For example, if Amazon orders 100 units and you confirm the order with 50 units, your confirmation rate is 50%.

Amazon typically aims for a vendor confirmation rate of at least 80% to minimise the risk of stockouts. If you fall below that threshold, make sure you review and adapt your order confirmation processes.

Receive Fill Rate

The Receive Fill Rate measures the number of units received for an order compared to the confirmed quantity.

This metric should track close to 100%. If it falls below this threshold, there’s often a process defect or catalogue error leading to unpaid invoices and chargebacks.

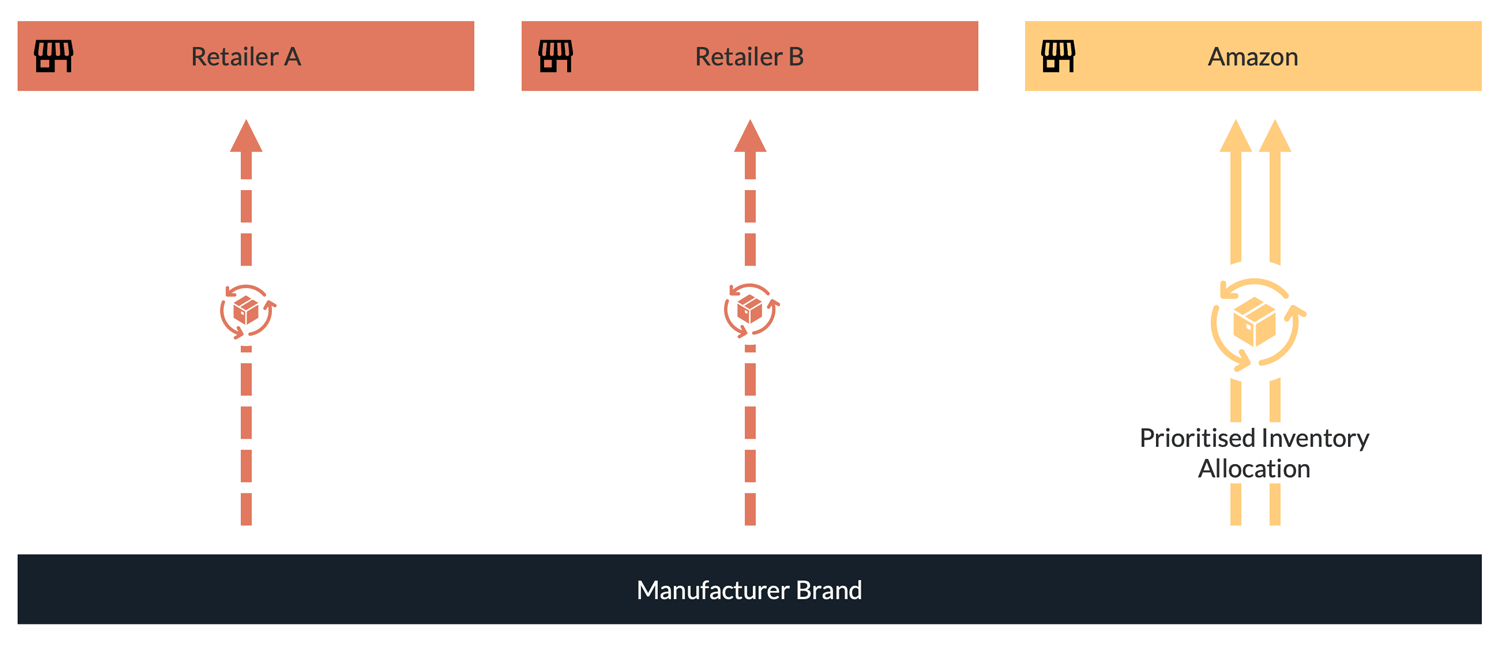

2. Prioritise your inventory allocation to Amazon

It sounds simple but can be very hard to implement: Getting your teams to prioritise orders from Amazon. That’s because other, larger retailers may get prioritised in your order process management.

If you want to increase your confirmation rates and product availability on Amazon, you must educate your business to prioritise orders from the online retailer.

That’s because treating offline and online retailers equally in your order management has one major flaw: It neglects that an out-of-stock situation is not the same on Amazon as in a physical store.

As we have already discussed, being unavailable on Amazon also means losing your sales rank and visibility in search results. And it takes a lot of time and media investment to regain these.

3. Review and correct catalogue errors

It’s easy to forget that Amazon once started as an online bookstore. Unfortunately, this means their catalogue was never designed to cater to as many different product categories as it does today.

As a result of the company’s expansion, many legacy issues still surface today. Catalogue errors that affect the number of products on a pallet or the inner packs in a case can quickly lead to availability problems.

For example, if Amazon thinks your case pack contains ten product units, but it’s only five, the online retailer won’t order enough to keep up with demand. This creates shortages that can significantly impact your availability performance.

To address these catalogue errors, work with your media agency, Vendor Manager or AVS Brand Specialist and repeat regular catalogue checks every month.

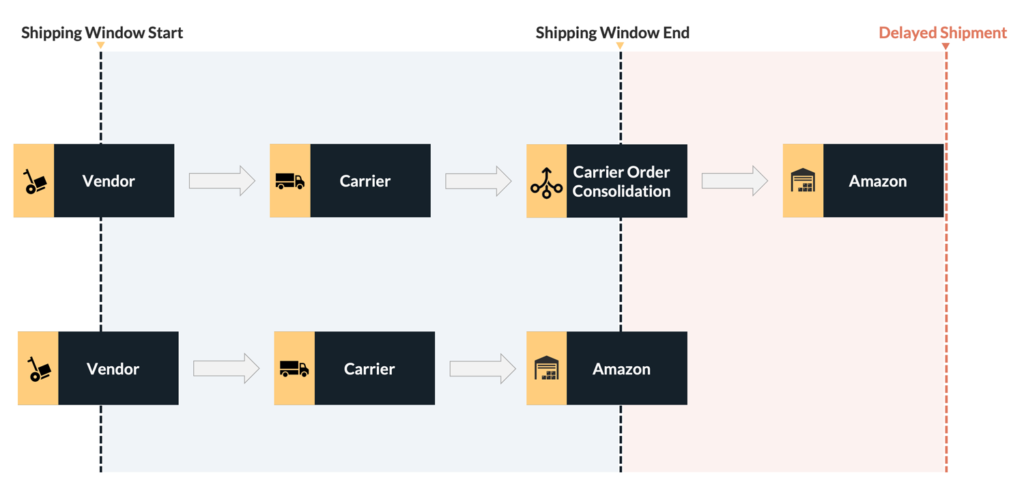

4. Avoid interm storage by your carrier

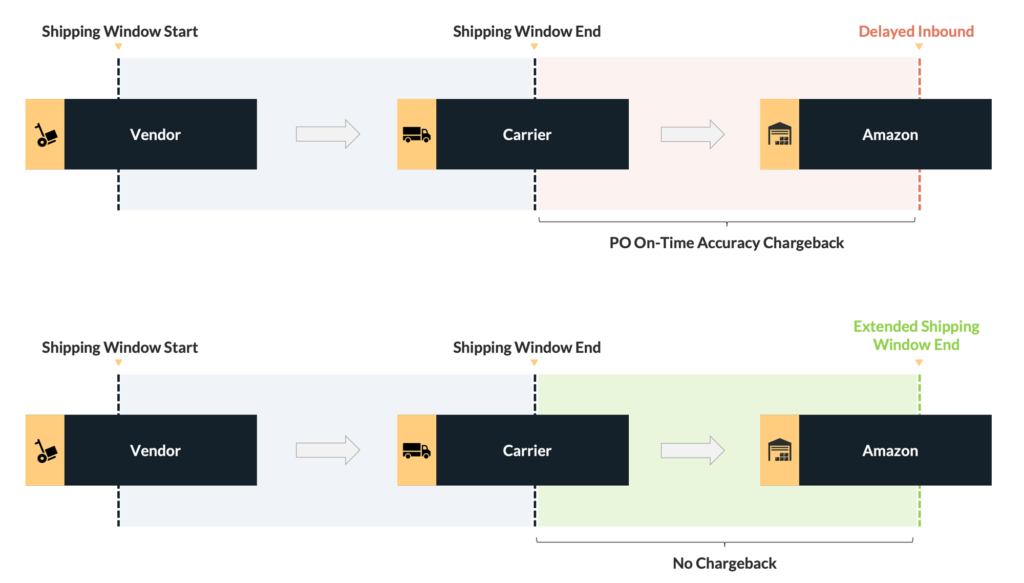

As a 1P Vendor, you know that Amazon is strict about receiving order volumes within the specified delivery window. But even if you work with an Amazon-preferred carrier, you might run into availability issues.

That’s because many carriers will put your order into interim storage during peak seasons. This happens if your order does not reach a full truckload size, as the carrier saves money by combining it with orders from other brands.

As a result, your goods get delivered outside the PO’s delivery window, even though your teams handed the goods over to the carrier on time. As Amazon doesn’t account for this consolidation, your products could run out of stock.

An effective way to detect this consolidation is to track the Advanced Shipment Notice (ASN) sent by your carrier. If you see that your carrier puts products into interim storage, I recommend educating them about Amazon’s delivery window requirements.

Should the problem persist after this step, consider adding a contract clause prohibiting this practice to your existing agreement or changing the carrier for your deliveries to Amazon.

5. Request the extension of delivery windows

Speaking of delivery windows: Make sure you ask for their extension if you cannot ship orders within the given delivery time. Otherwise, Amazon’s algorithm will place orders too late, increasing the likelihood of stockouts and chargebacks on your account.

You can review your vendor lead time in Vendor Central under the Retail Analytics Inventory Report. It measures the time it takes from when an order is confirmed to when it is delivered to the Amazon fulfilment centre.

The online retailer expects brands to have a lead time of 3 to 5 days. If you cannot deliver goods within this time frame, ask your Vendor Manager for an extension.

6. Automate your order management

Most vendors receive their orders from Amazon weekly. But especially in peak quarters, the order confirmation process can quickly become very time-consuming.

So if your warehouse team is still manually handling the order management process, it’s time to automate it. This will reduce the time spent managing orders and improve your vendor lead time with Amazon.

Amazon uses EDI (Electronic Data Interchange) as a standard to receive order, shipment and invoice messages from vendors. This makes it easy to find service providers who can help you automate your order management processes.

If you’re looking to automate your ordering mechanisms, I suggest reaching out to KhooCommerce or TrueCommerce.

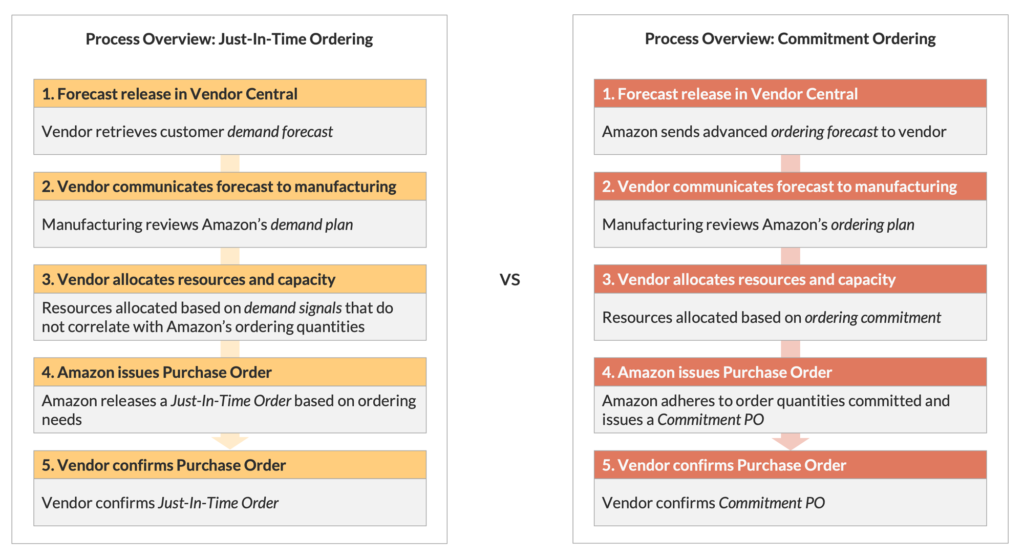

7. Enhance forecasts with Amazon’s Commitment Program

The ability to accurately forecast demand is one of the most critical factors affecting your product availability with Amazon. Thankfully, the online retailer shares its P70 forecast with every supplier in Vendor Central.

However, this forecast is based entirely on consumer demand. And therefore doesn’t translate well to how Amazon will actually order from your account.

But there’s good news: Since 2023, Amazon has offered selected vendors access to its Commitment Ordering Program, which provides insight into Amazon’s latest order forecast.

This additional data stream can significantly improve your product availability with the online retailer, as Amazon commits to placing these order quantities at the forecasted value.

To negotiate access to the Commitment Ordering Program, make sure you reach out to your Vendor Manager and make it part of your annual vendor negotiations.

Please note: The Commitment Ordering Program is only available to suppliers with access to Vendor Managers in the US and selected European markets.

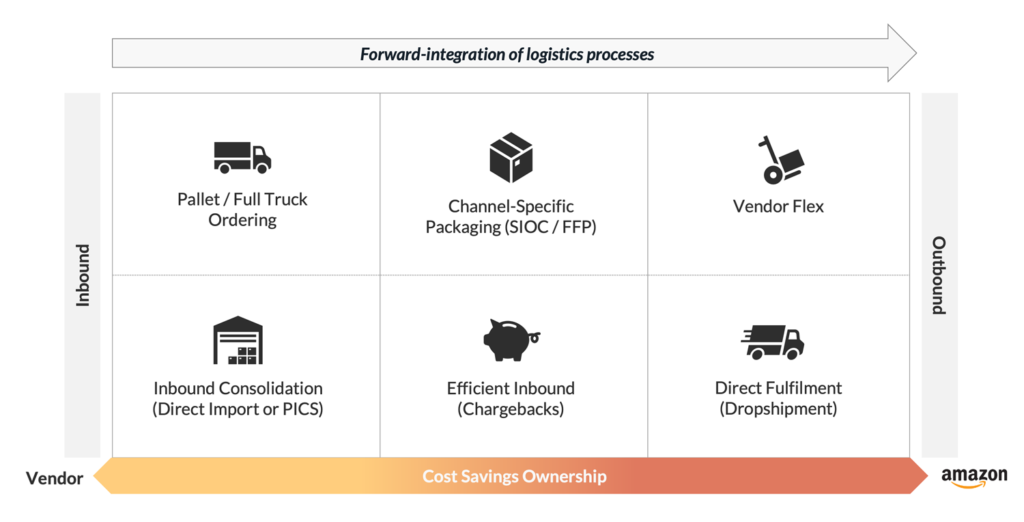

8. Improve your supply chain with Amazon

Improving your product availability on Amazon doesn’t have to be expensive. In fact, most brands could save money by consolidating their supply chain with the online retailer.

Vendor Managers can offer a variety of programs tailored to the unique needs of your vendor account:

Arranging a Vendor Flex or Dropshipment setup can help overcome capacity constraints at Amazon fulfilment centres during peak seasons. While consolidation programs like PICS can help your teams deliver to Amazon faster and at a lower cost.

When implemented correctly, these supply chain initiatives also indirectly improve the availability of your products by eliminating operational bottlenecks that hinder an efficient order fulfilment.

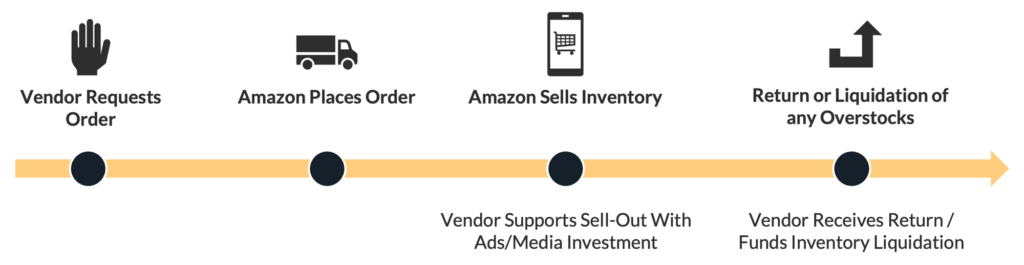

9. Use Born-to-Run for new and seasonal products

If you sell many new or seasonal items on Amazon, you know that Vendor Managers don’t like placing early orders for these products. And even if they do, it may not be enough to keep the items available.

However, the problem isn’t the product. It’s that these listings lack a sales history. This makes them extremely difficult to forecast for the online retailer.

Instead of waiting for your buyer to place an order, use Amazon’s Born-to-Run program instead. It allows brands to directly request manual orders for new or seasonal items in Vendor Central.

So if you struggle to keep products in stock that don’t have a minimum of 2-3 months of sales, you can use this program to improve the availability on your account.

10. Diversify your sales dependency via Seller Central

After going through the previous steps, you may wonder if there is anything else you can do to improve product availability. Spoiler alert: Yes, there is!

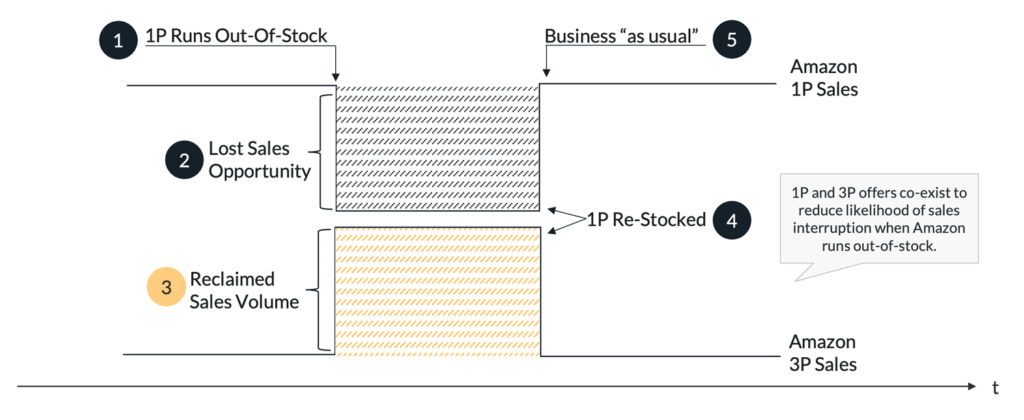

As you are trading with a marketplace retailer, you don’t just have to list your products on Vendor Central. You can also sell them through a Seller Central (3P) account.

This hybrid setup allows you to still fulfil shopper demand through Seller Central if Amazon 1P runs low in inventory. As a result, your product remains available, which helps maintain the sales rank and visibility of your listing in Amazon’s search results.

Note that in the US, Amazon may apply its Standards for Brands Policy to prevent you from moving selection from Vendor to Seller Central. You can learn more about it here.

Final thoughts

Reducing your stockout rates on Amazon isn’t rocket science. But it takes a structured approach to identify the root cause of availability bottlenecks and address them with the right actions.

To do this, review your stock levels and availability metrics in Vendor Central at least once a week. This ensures you spot and address any trends that can increase the risk of supply shortages early on.

Need help assessing your vendor performance with Amazon?

If you want to better understand your vendor performance with Amazon, get in touch. I offer tailored vendor audits to uncover your full margin potential with the online retailer.